Build Your Own Wood Turning Lathe

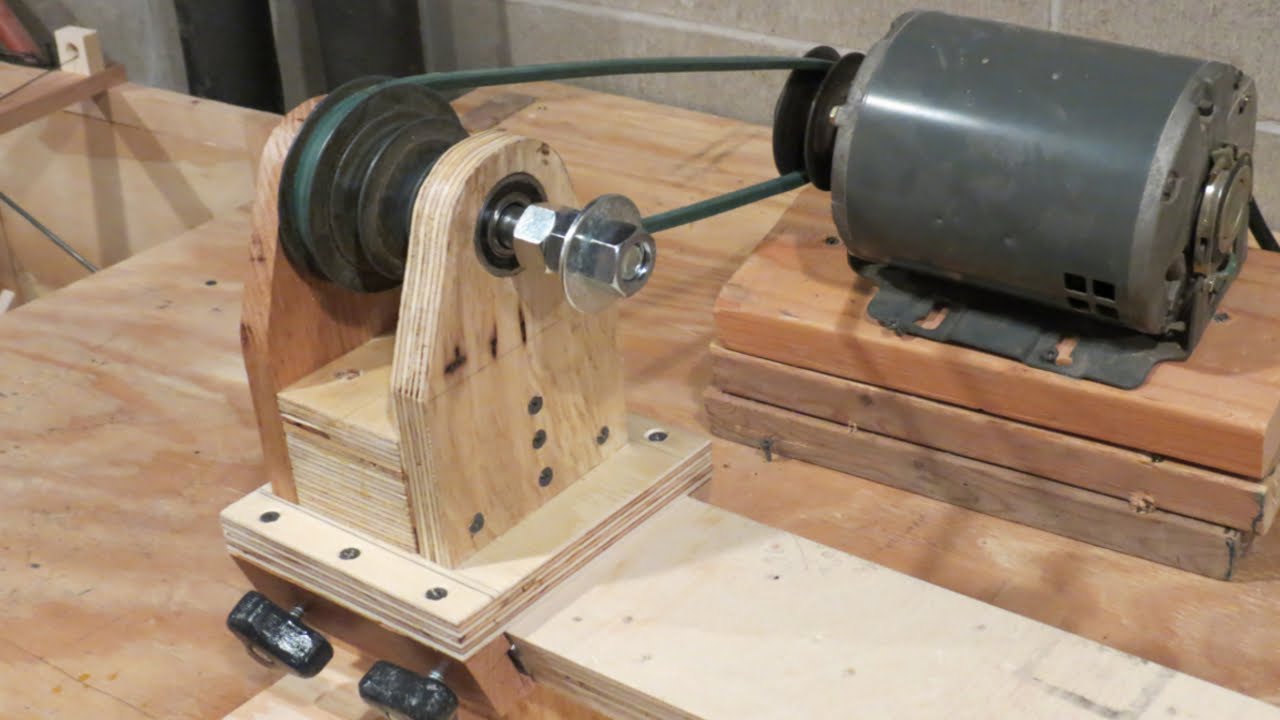

The headstock is basically the part of the lathe that houses the main drive shaft which will spin your wood.

Build your own wood turning lathe. Building your own tools is a. All you need is the desire to have one the gumption to do so and the intestinal fortitude to say I. The first thing you have to decide is what kind of lathe you want.

Considering that electric motors commonly come at 2400 or 2800 RPM as well as the cheaper low speed ones finding the right motor is part of the fun of creation. You need to move this to the side when you are putting wood onto the lathe. It needs to take drive from a motor transfer it through a belt to a shaft that you will attach the wood youre working on.

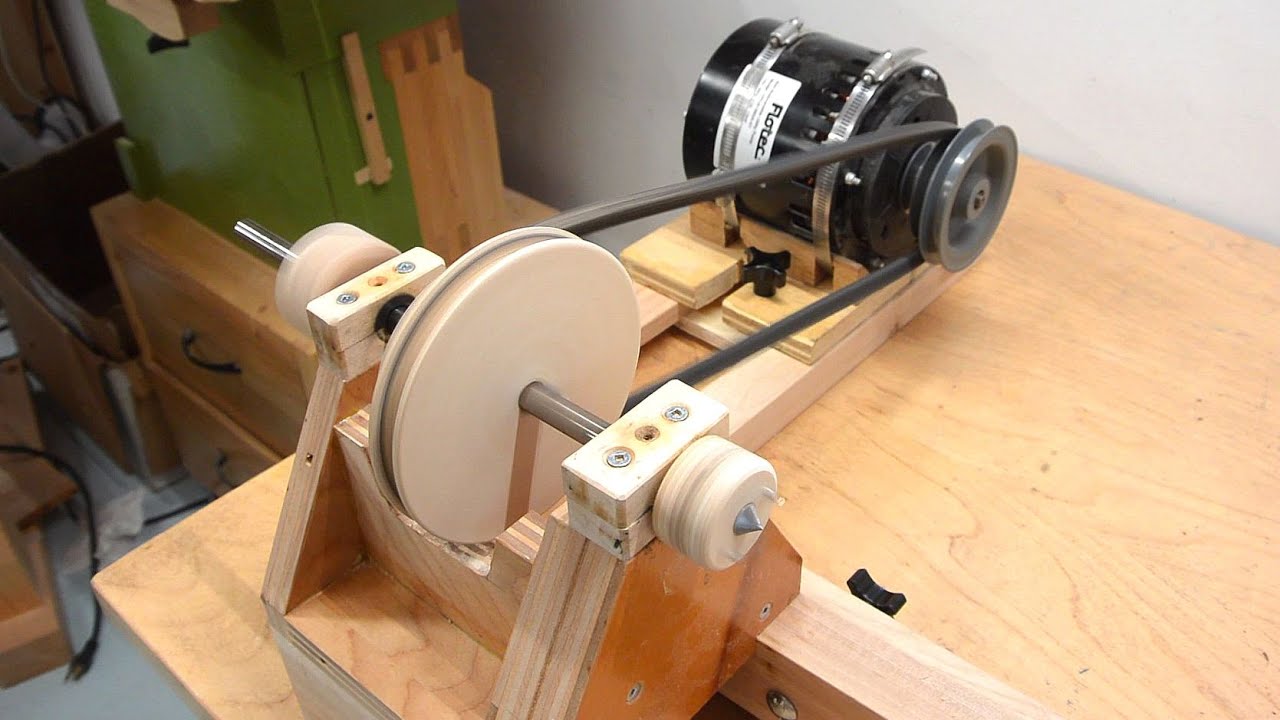

Finally you have your tail stock. You lathe should look like this. This book will help you save money on woodturning expand your abilities and master new challenges giving you more success and confidence at the lathe so you can pursue any style of.

Here you will learn how to do with your own hands homemade wood homemade electronics Christmas c. In your tail stock put the live center. I made a drill powered minipen lathe using roller blade wheel bearings and a couple of scrap pieces of plywoodFor futher information check out my insructab.

Make sure the wood is properly secured to the lathe before you turn it on. You can buy your own wood lathe or build your own. See more ideas about wood lathe lathe wood turning.

If the turning project starts to wobble and lose its center you will need a steady rest to keep the turning project. Pick up your spindle blank and alight the awl hole with the point on the drive spur. Also a wood lathe does not need the complicated tool rest that a metal lathe has.