How Much Does It Cost To Start A Cnc Machine Shop

Lathes alone can cost anywhere from a few thousand dollars to tens of thousands and many shops have several pieces of equipment.

How much does it cost to start a cnc machine shop. CNC machines arent inexpensive. Until you start looking into it you might not realize just how cost-effective and strategically savvy it can be to buy second-hand equipment rather than automatically opting for a brand new model. Press the Calculate button to figure out the machines hourly rate.

It can report turnover of 300000 to millions. If playback doesnt begin shortly try restarting your device. From their toolroom mills and lathes to their small production machines you can expect to find entry level CNCs starting at about the 30k range.

Next to the field is a Calculate button that brings up this calculator. Either buy your mill new or carefully test a. The prevailing rate structure must allow you to recover your operating expenses.

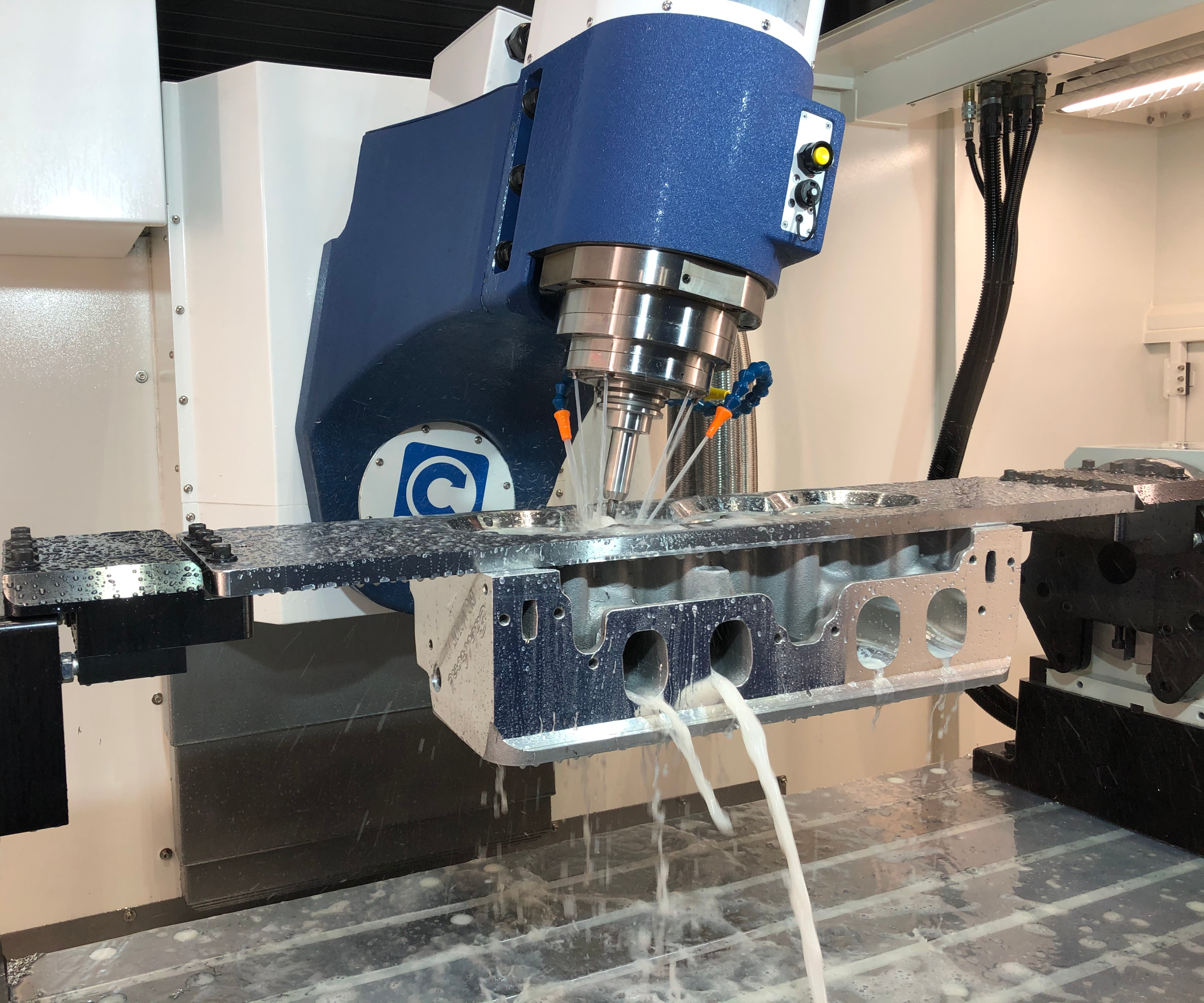

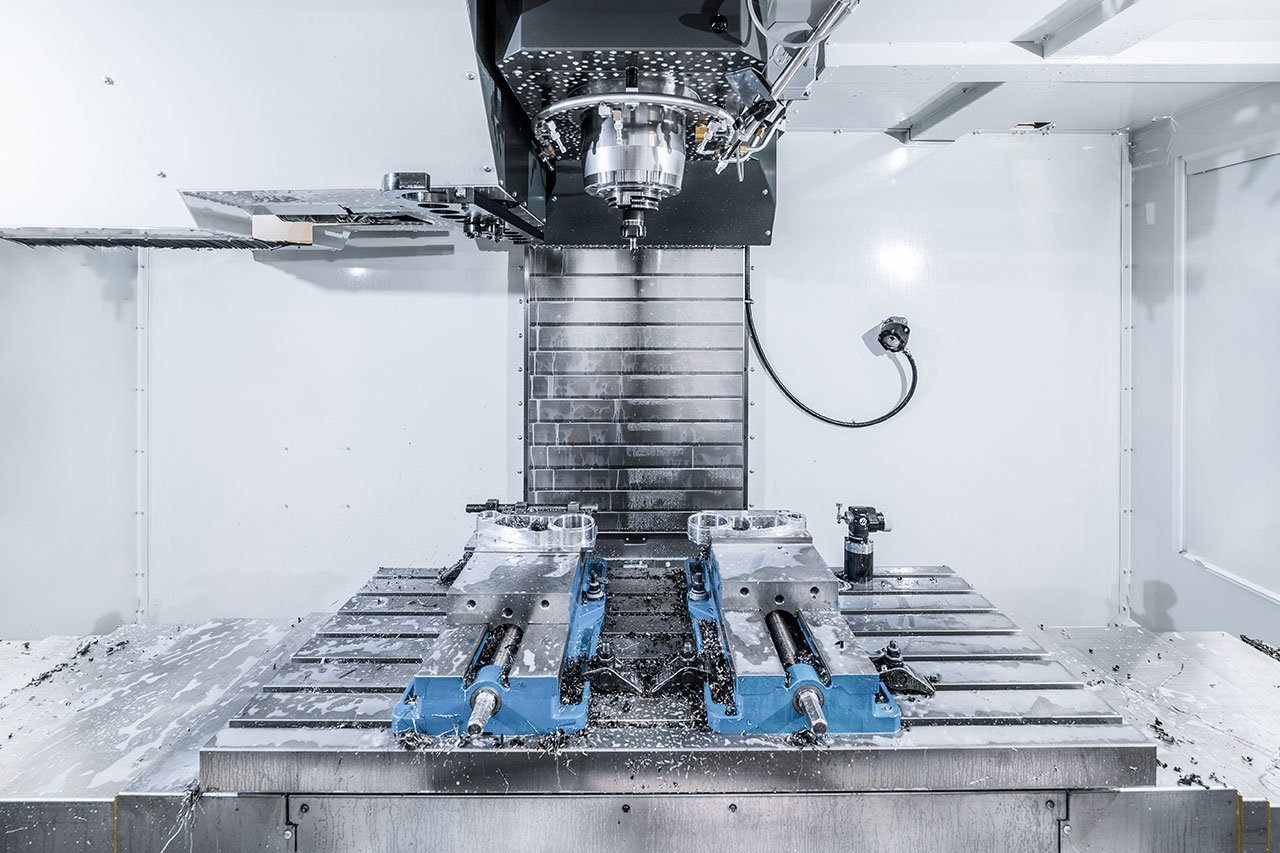

Scaling a CNC Precision Shop for Growth. You can find the Machine Hourly Rate Calculator on the Machine Profile under the Setup Basics tab. Starting out small with a few manual machines may be the only path for those who do not have all the money and client base to open a full service machine shop.

Multi-axis machines are more expensive to run so will cost more. On the other hand there is a boatload of competition for the single-mill shop right now. Simple calculation is markup 1 owners salary benefits annual earnings goal annual service hours machine labor overhead cost per hour.

It is common for someone to start-up with one manual milling machine so they can build capital for more machines such as a lathe horizontal bandsaw vertical bandsaw surface grinding machines etc. Add in electrical tooling air saw and a handful of deburring equip. Videos you watch may be added to the TVs watch history and influence TV recommendations.