How To Build Your Own Cnc Wood Router

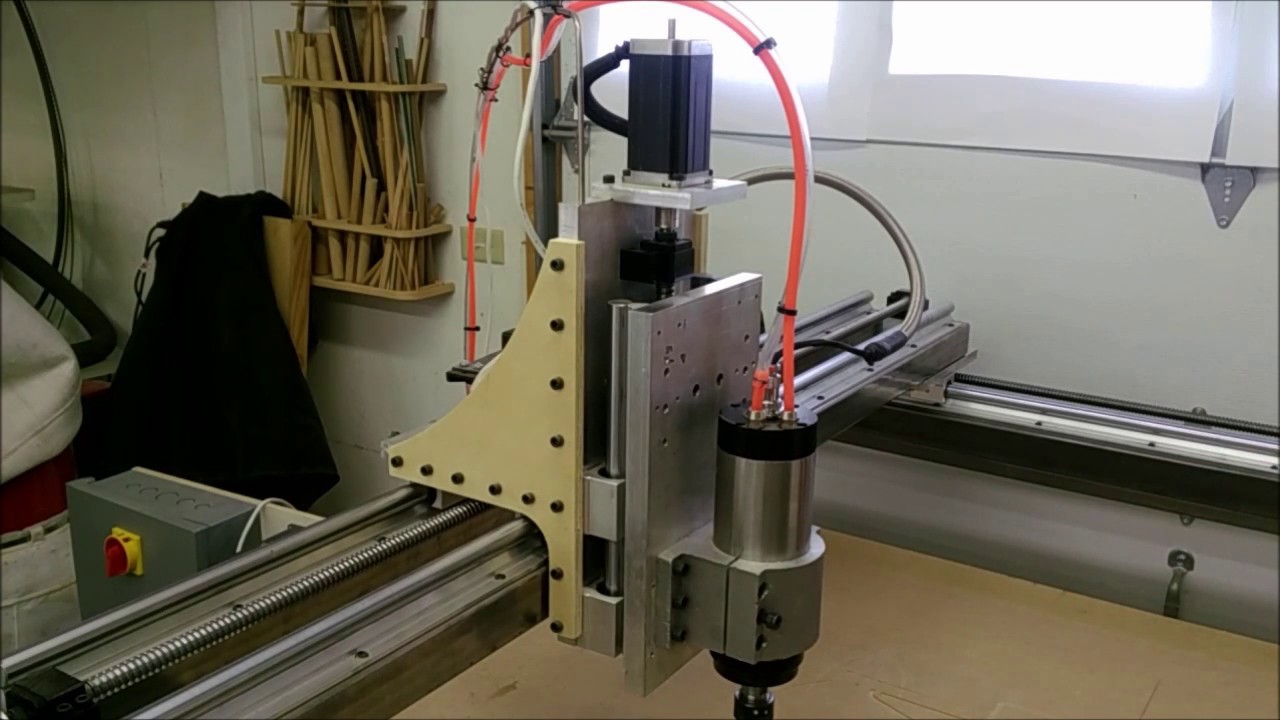

This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

How to build your own cnc wood router. A CNC machine is probably the most useful tool a hobbyist can own but the price for a CNC machine on the market is way more than the average hobbyist is willing to spend. Assembled Option includes the complete CNC Router andor Laser is. Building your own 3-Axis CNC router is both fun and educational.

There are 3 steps to the project Construction Software Manufacture. He added an emergency stop button which any experienced CNC operator can tell you will come in handy sooner or later. The mechanical parts he had to.

Get the step-by-step plans for this Shop-Built CNC Router here. Making musical instruments is also a good way to run your CNC machining business. This program is a guarantee that in just a couple of hours youll be able to put together your own CNC machine or smart Saw as I like to call it.

Shipping cost will be provided when parts are ready to be shipped. I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily. All you need to do is assembl the machine or find someone in your area that can assemble the machine We are building a list of individuals to help assemble in your area.

It would be just like a professional is next to you guiding you every step of the way. We thought it was time we introduced our own shop-built CNC router. With a working area of 24x48 you can build this for a lot less than the cost of a similar commercial CNC router.

Youll have your own step-by-step video tutorial plus a written manual and a 3D app to go by its side. Drill and tap some mounting holes in the edge of each bearing and. But Ray built the moving-gantry CNC.