How To Make A Parting Tool Holder

I had a short production run I needed to finish and part of the process required a small groove at the end of the piece.

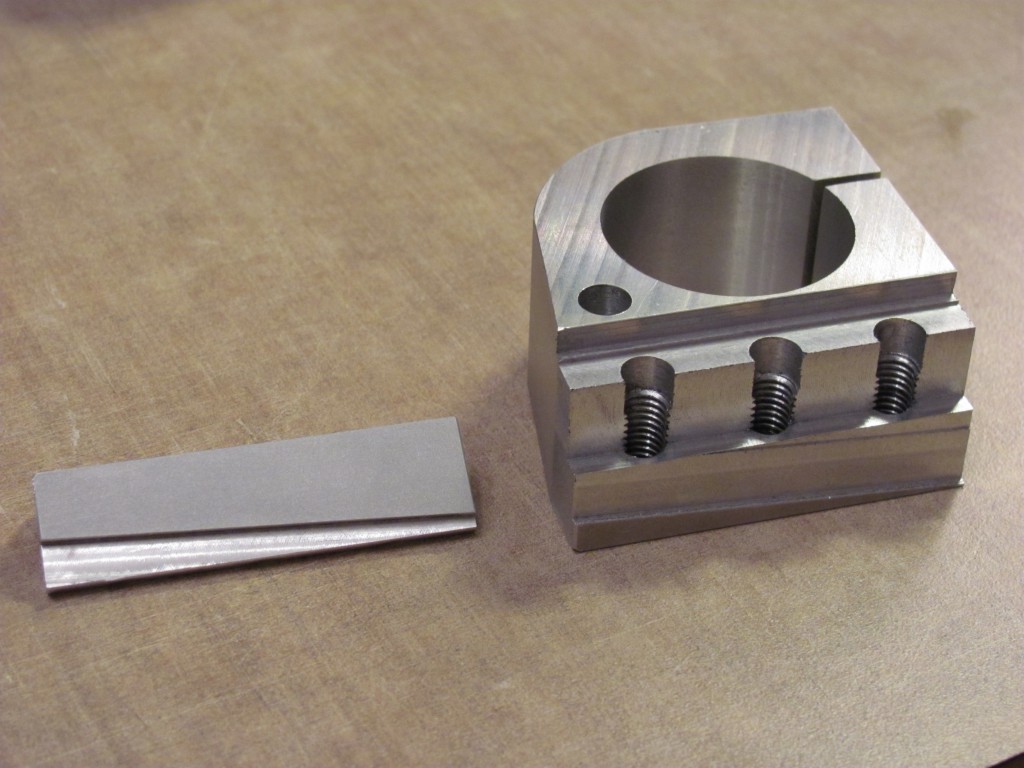

How to make a parting tool holder. Now lock the half nut in the engaged position to keep the carriage from moving during the parting cut. Meet Staffan and Johan the brains behind the new ingenious way of parting along the Y-axis which challenges conventional machining. Remove from chuck and drill and tap top holes.

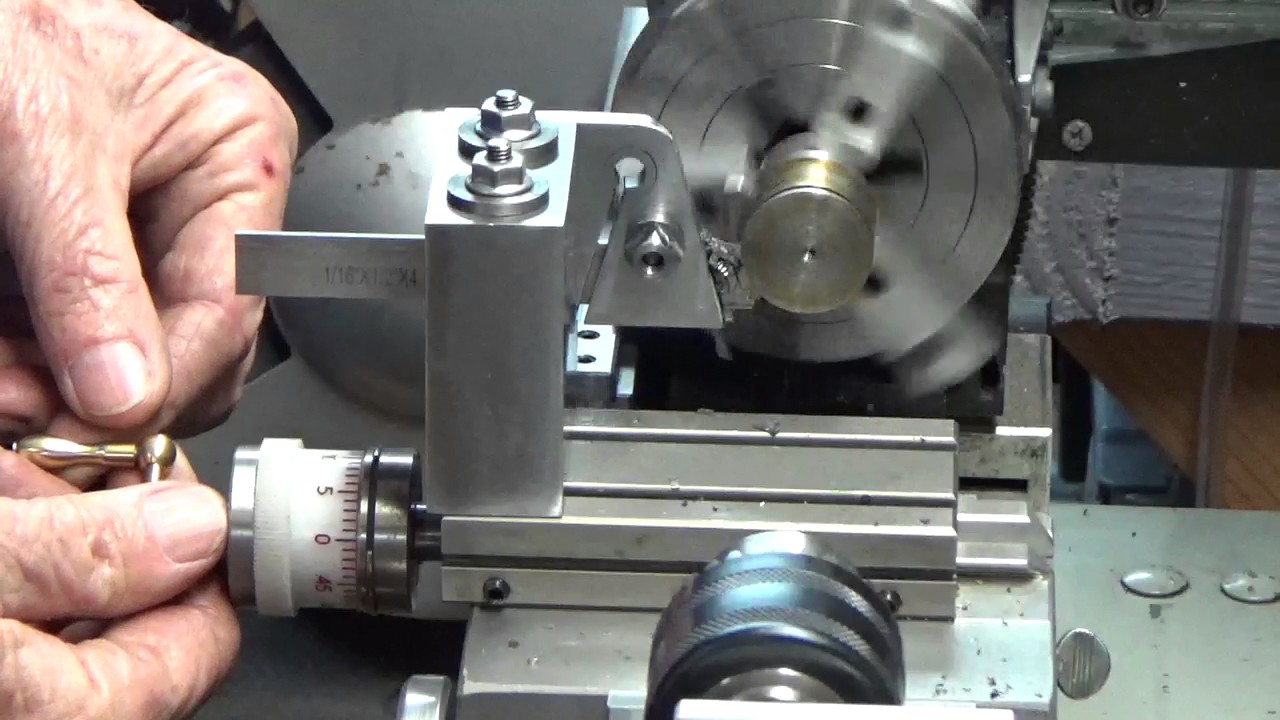

C any other designs that basically does the same thing like parting from the opposite side of the spindleetc. Ive made a couple of turning tools with carbide cutters and some with HSS cutting blanks all turned out to be very useful. Loosen the tool post align the edge of the toolholder flush with the 1-2-3 block and re-tighten the tool post.

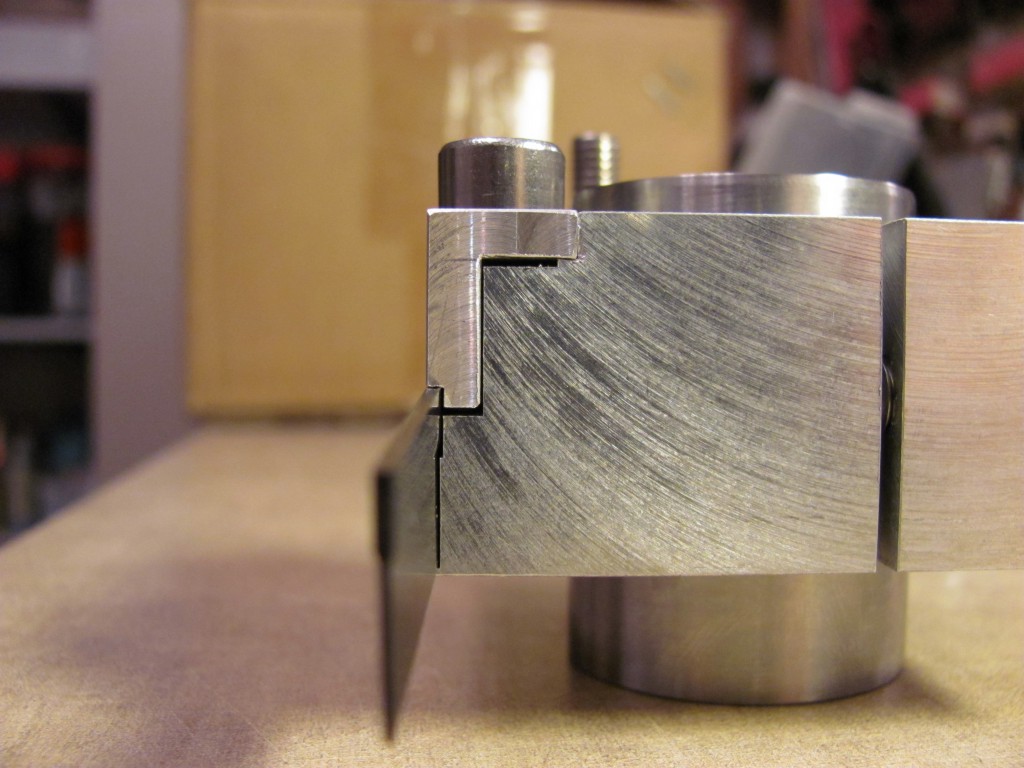

Repeat for 2 of the other sides. This means that when this tool holder is being used the shank must be at 45 degrees to the left. Use a master square to set the tool holder square with the lathe chuck and tighten the nut to lock the tool holder in place.

Its made from scrap. The easiest thing to use was a part. Facingturning holder but holds the parting blade inverted.

Successful chip control Cutting tools featuring over- and under-coolant delivered with high precision means you can control both chips and temperature for highly productive and problem-free parting and grooving. The problem of snatching with HSS parting blades. To truly advance parting off operations it is not enough to develop a new toolyou need to develop the method for using it.

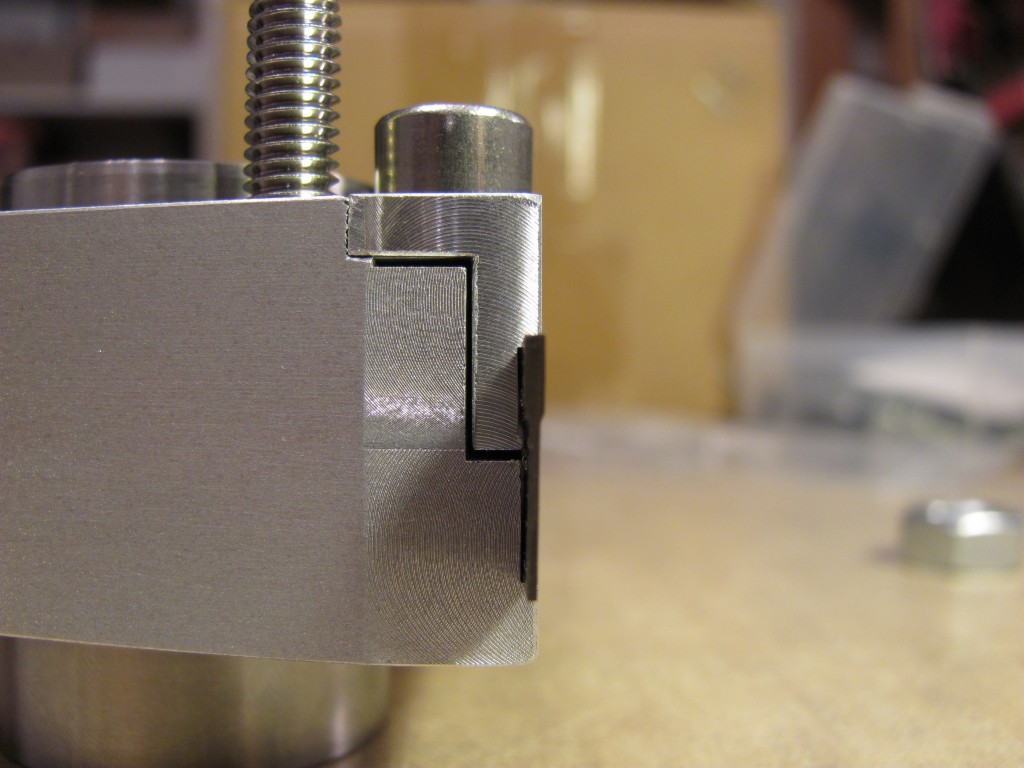

To ensure the parting tool is perpendicular to the face of the chuck you can use a 1-2-3 block whose surfaces are ground to be parallel to one another. For 1 long try the front wedge for a sliding fit. Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting.