How To Make Checkering Tools

The tool is used to complete the repetitious bulk of the checkered panels.

How to make checkering tools. Ramelson is one of the only US-based manufacturers of screwdrivers checkering tools and other gunsmithing supplies. Its best to start the job with a checkering panel pattern cut from a piece of white paper thinner than copy paper is better so a pattern appropriate for the particular stock undergoing surgery can be chosen - with an eye toward overall size and outlineshape. This is the most common type of checkering.

The cutters are attached to the tools shanks with a steel rollpin that slips through a hole in the tool shank and cutter. Watch as Larry Potterfield Founder and CEO of MidwayUSA makes a checkering tool from a length of dril. Once thats done its just a matter of moving across the surface one line at a time with the double-head tool.

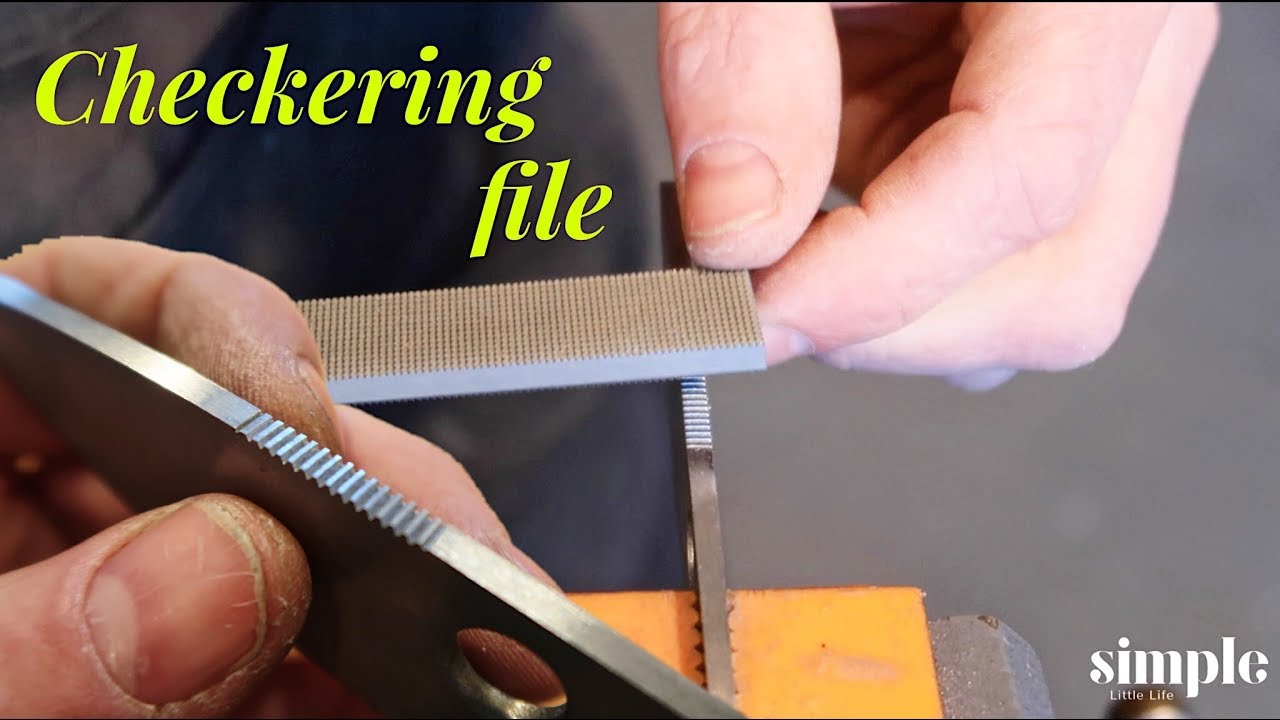

Dont try to evenly space your stipple marks. To make the tool you need a small triangular metal file the smaller the better. You will use this one the most.

The single-line cutter is used to lay out the pattern and the master lines - and to deepen the checkering to full depth. Hold the tang with a pair of pliers and heat the forward two inches of the file to a dull red. A four-inch size with as little taper as possible is ideal.

Scribe this then use a single line tool to cut a master line. Next I make the two master lines within the pattern at a 45 degree angle or thereabouts and they are the starting point of the checkering. As you do move the stippling tool around inside the panel in a random manner.

A single-line cutter is indispensable. In the simplest terms checkering is nothing more than two series of parallel lines intersecting at about a 33 angle. The grooves are cut under a 90 degree angle sometimes 60 degree.