How To Make Your Own Cnc Wood Router

This program is a guarantee that in just a couple of hours youll be able to put together your own CNC machine or smart Saw as I like to call it.

How to make your own cnc wood router. Below is a general outline of how a CNC router works and the steps required to create something using one. Like many CNC router projects the wood needs to be flat and sanded down with grade 180-240 sandpaper. CNC wood router can make many instruments like piano guitar violin and others.

To make a bearing out of plastic just drill a hole the same diameter as the corresponding shaft. Drill and tap some mounting holes in the edge of each bearing and. By using calipers dial indicators and a machinist square you will need to measure precisely.

Kinetic sculpture - This amazing CNC sculpture will make it look good on your wall. Get the step-by-step plans for this Shop-Built CNC Router here. For just a few dollars the student who built this machine was able to make a huge improvement to the look and performance.

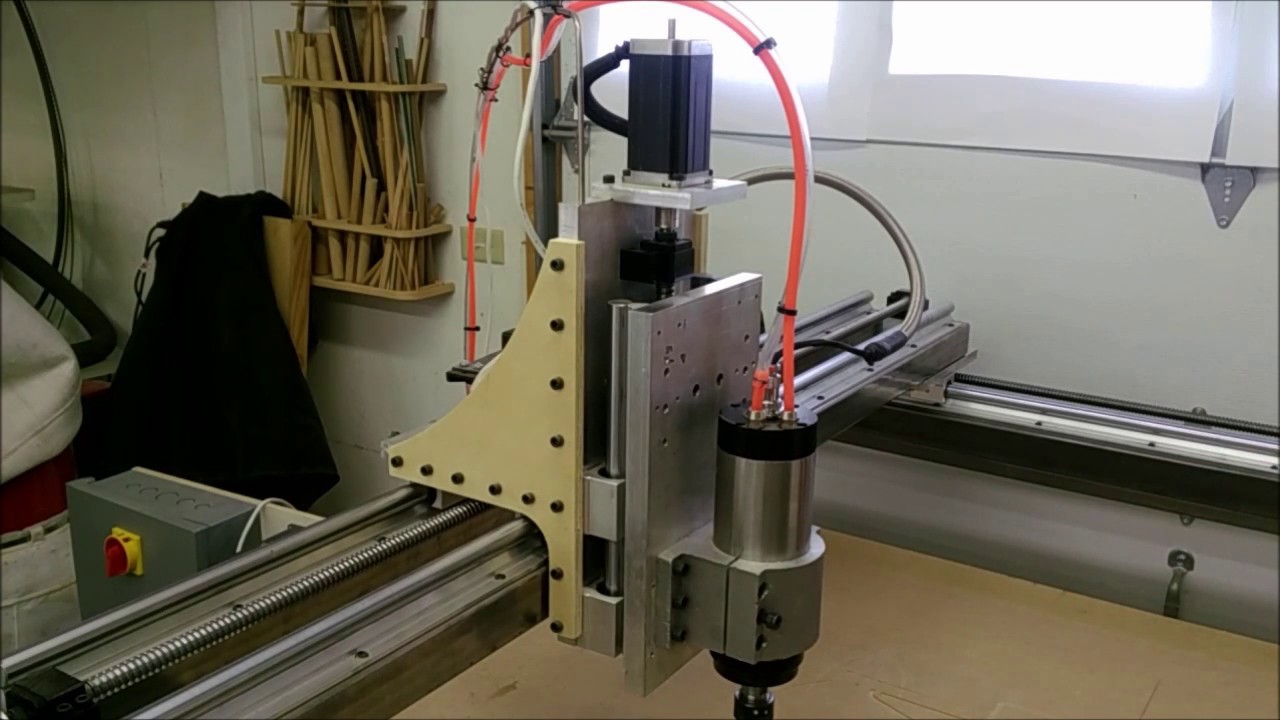

If you are building a 3 axis CNC router you should buy a kit consisting of three sets of linear rails and two linear bearings per rail. Basic digital marketing starting with a social media page is the first step to selling your CNC router business. Build your own CNC explains how to build program and manufacture your own products on your own machine.

The basic options to drive each axis are. Before assembling your machine ensure you have these tools. For this example were going to look at a simple turtle jigsaw.

With 20 inches wide the kinetic sculpture can run several hours by a single winding. Timing belts rack and pinion and drive screws. This design can be amended and would suit machines from 2400mm x 1200 down to 1200 x 900mm.