How To Manage A Cnc Machine Shop

AB Machining and Fabrications 10.

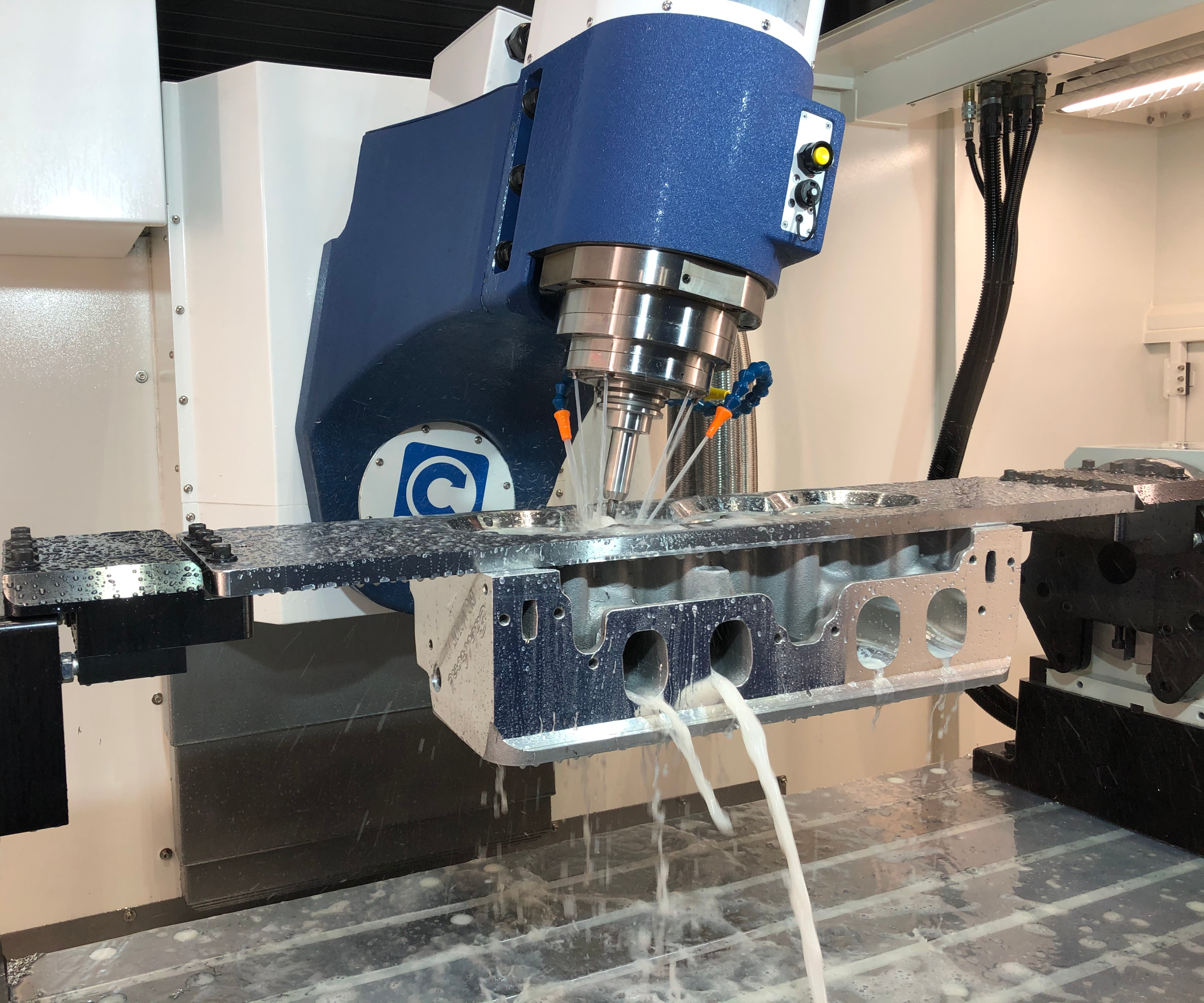

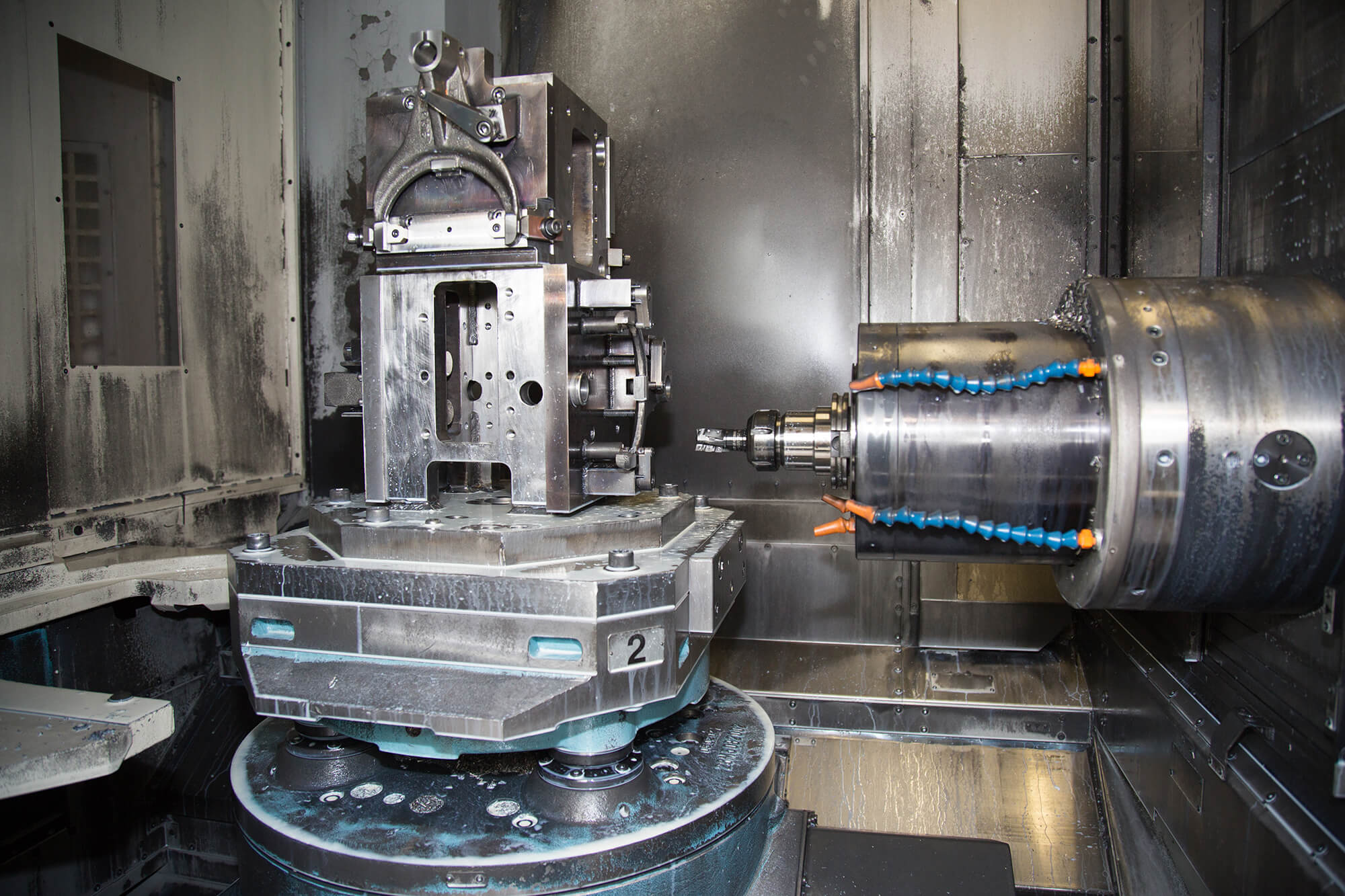

How to manage a cnc machine shop. A CNC machine shop is a high profile manufacturing facility that will deliver your orders if you need metal plastic and other parts for different machine components. Before the advent of the CNC machine shop all machining equipment was operated manually or mechanically which meant that the accuracy of machined parts depended largely on the skill of the machine. Depending on the capabilities of the CNC machine shop they can concentrate on specific industries.

It should go without saying that CNC people directly affect the productivity of the machine or machines on which they work. In machine shops production is critical to revenue. CNC Shop Owners and Managers use this as a guide for which skills are scarce.

Because a companys productivity is directly related to the productivity of its CNC machine tools CNC people should be considered among the most important people in a company. How digitalization has changed the machine shop Computer Numerical Control became commonplace in the latter half of the 20th century changing machine shops forever. Machine Shop Organization Ideas.

As a machine shop manager there are always many moving parts no pun intended to manage throughout day-to-day operations. Laurentian sniper1rfa fciron liked this post 05-06-2012 0930 PM 12. Every person working on a project has his own role and should garner respect from his peers on site.

CNC Programmer and Machine Shop Supervisor. CNC Machining Machine Shop Scraps of wood and metal likely cover the surface of your workshop as proof of how hard you work in that space. Delays in production can lead to increased costs and missed deadlines which ultimately can lose a business clients.

Continuous improvement is necessary but managing the rate of change is important. 75000 - 85000 a year. As more tech-savvy shop owners and workers begin to embrace the next generation of machines and tools machining efficiency is expected to soar.