How To Program Cnc Wood Router

An advanced CNC wood router can achieve the processing work in a 3D level.

How to program cnc wood router. Ad At Surplex you will find used machinery and industry equipment at best prices. Write G code directly for programming 2. Common Sense About How to Program A Woodturning Project for CNC Wood Lathe.

The process of designing a part for your CNC router begins with a CAD program. You can create a CNC program in any text editing application. Allow the router to engrave the substrate.

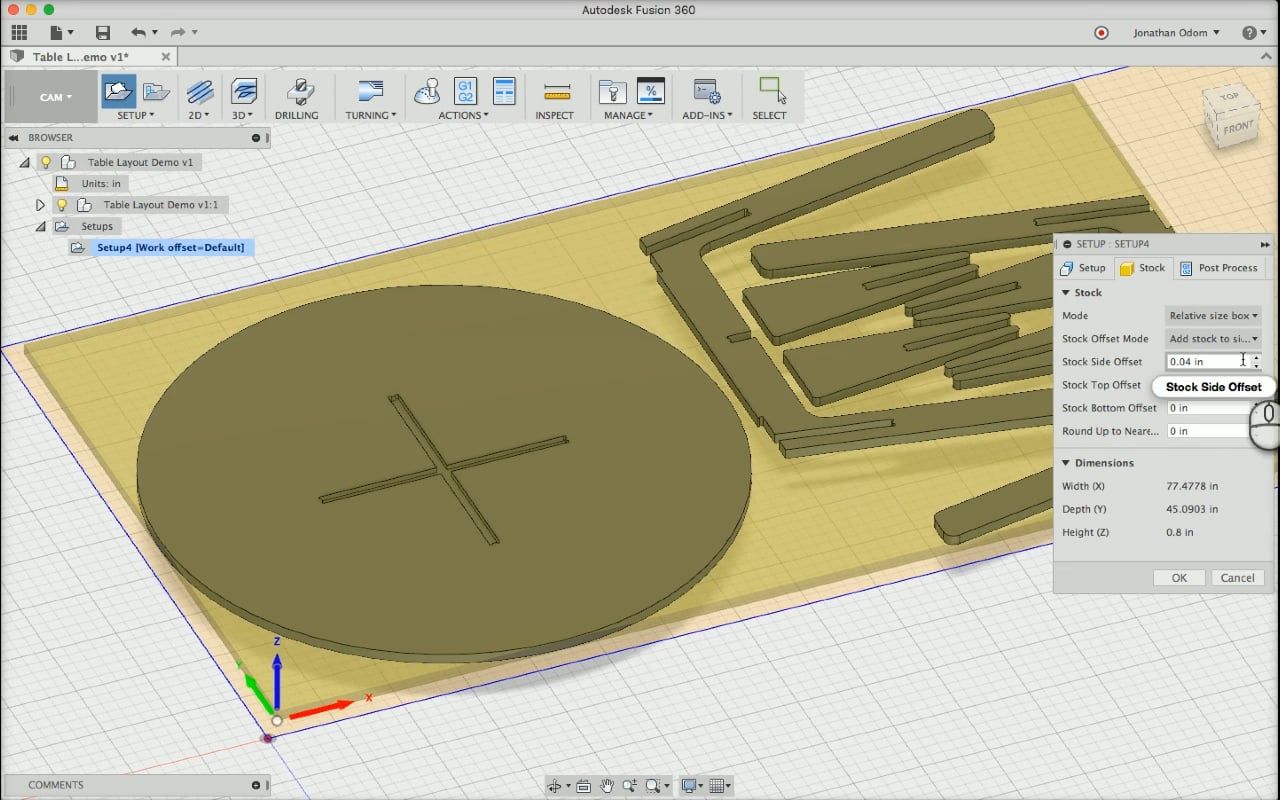

From design to manufacturing stage a wood CNC router uses three different kinds of software namely CAD CAM and CNC control software. Start the CNC router and begin the program by pressing the Start or green button. Up until the past 20 years or so CAD design had been limited to those who could afford expensive software programs.

You need to fix the workpiece onto the machine machine vise spindle or similar work holding device and attach the required tooling end mill drill bit to the machine component. It can punch holes on the work pieces or groove a part of the material and create a tiny rabbet. Become a better woodworker by viewing these how-to woodworking videos.

How to make Wooden Gears on a Cnc Router or Mill To make involute gear wheels you do not need an expensive cnc gear cutting program. Other CNC routers may have other types of buttons to signal this command. Place your substrate under the drill head and turn on the CNCs vacuum to secure it in place.

It is quite easy and makes for a fun cnc project. Before running the CNC program prepare the machine for the operation. The CNC Machine or Router is a computer controlled cutting machine that can be used for cutting various hard materials such as wood steel plastics aluminum and foams.