How To Sharpen Carbide Metal Lathe Tools

Apply layout fluid to the top surface and allow it to try completely.

How to sharpen carbide metal lathe tools. How to sharpen lathe cutting tool first of all we must choose the right grinding wheel. Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. Be sure you will get the best out of more than 4000 used machines and tools.

Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. When you sharpen a lathe tool bit youre really re-drawing a number of critical angles. They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with.

With steel you can use 10-20 degrees but never try to use a tool ground for steel on brass. At present the commonly used grinding wheels are alumina and silicon carbide. For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools.

It will grab and possibly rip the stock from the chuck or damage the lathe itself. This video shows how to sharpen carbide cutting bits. But considering the cost of carbide tools it makes sense to get the most use out of.

Lathe tool sharpening is important to making smooth consistent cuts. In this video I explore different aspects a slow speed grinding. Using a sharp object mark a point roughly 23rds of the way across the top and 12 down the side.

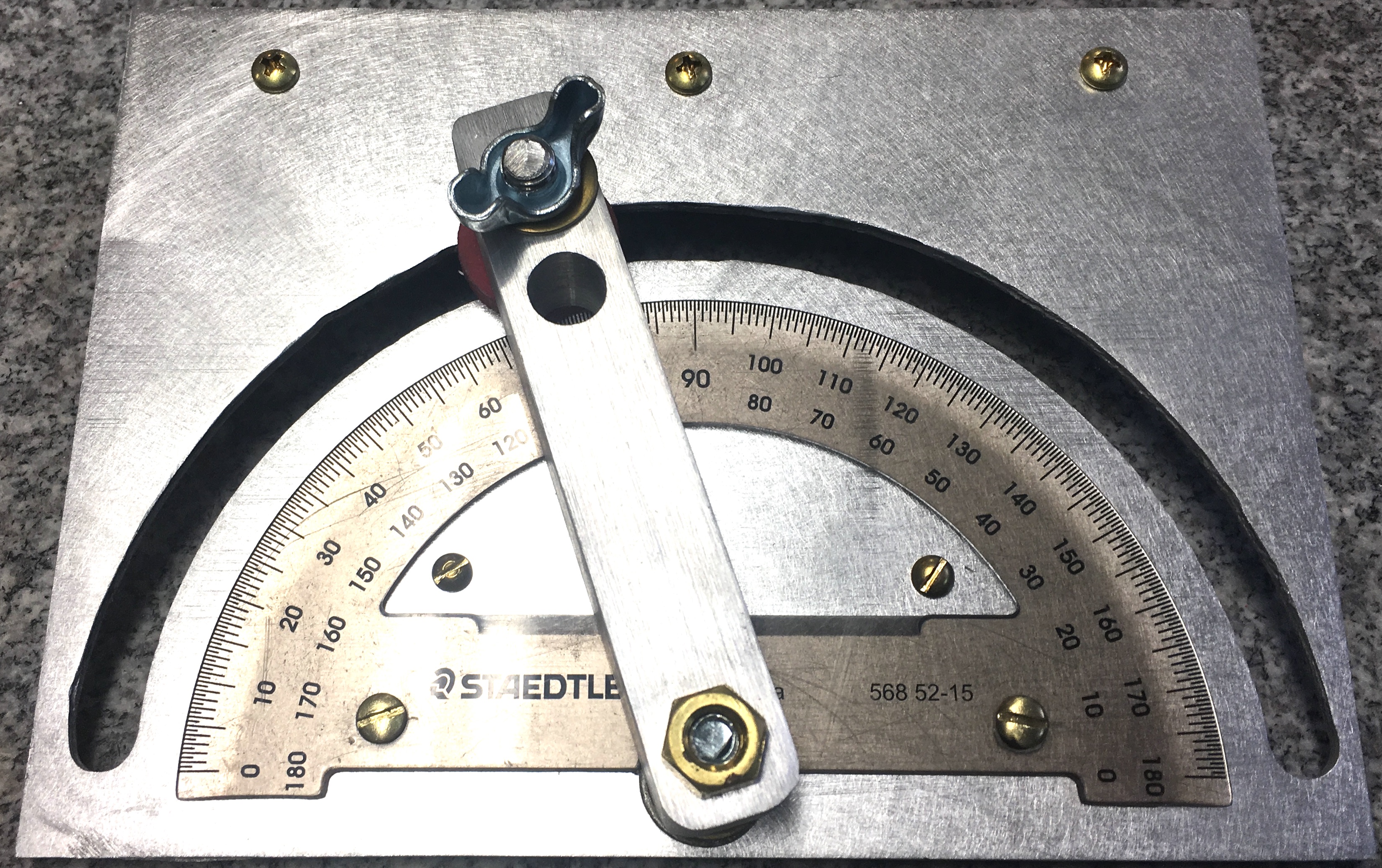

Shown below is what Ive put together to achieve the level of accuracy desired. Trusted China Suppliers Verified by SGS. Be sure to have some lapping fluid on hand to use as a lubricant.