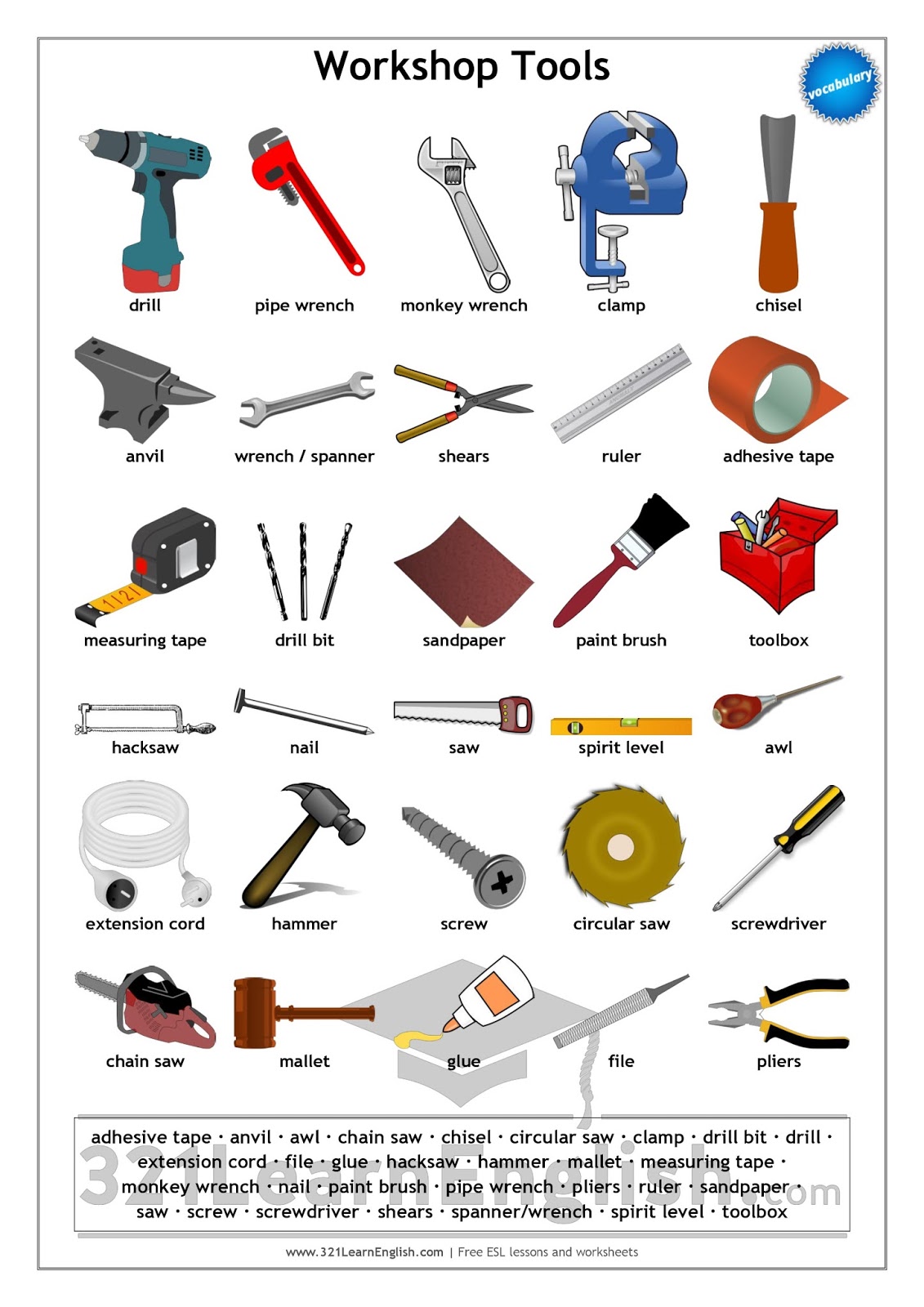

Study Of Different Types Of Hand Tools Used In Workshop

Soldering Tool Stand 9.

Study of different types of hand tools used in workshop. To become skilled with these power tools and hand tools you must use them. Richard Sennett Introduction Having just the right tool for the job makes all the difference in getting the job done quickly and correctly. Farm Jacks What farm jacks are used for.

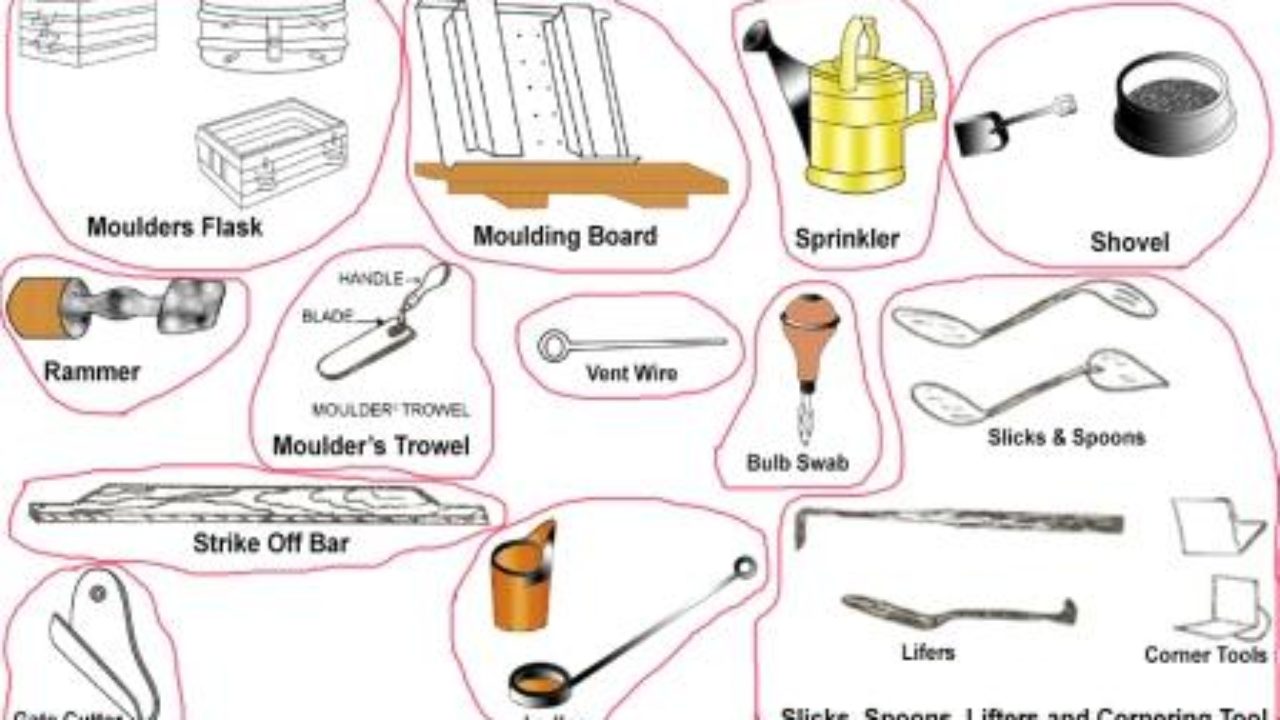

Introduction to sheet metal shop use of hand tools and ac cessories eg. It is a hand operated tool used to bore small holes for starting a. Allow for larger through-holes to be cut.

Holding tools are also known as Work Holding devices in the Fitting workshop. These are mechanical tools such as drills hand cutters and dremels. Remove sharp edges finish fillets and other interior surfaces Fig124Sharp cutting teeth are provided on its surface for the purpose.

They also absorb shock force which occurs when an item is dropped which stops the worker being pulled down at the same time which is particularly helpful if you are working with heavy workshop equipment. Different types of hammers hard and soft mallet sheet and wire gauge necessary allowance required during job. Slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising.

This chapter looks at fourteen different categories of basic machine shop hand tools and how they are used. You should also study the manufacturers operator and maintenance guides for each tool you use for additional guidance. As the hand-operated tools are much simpler and as the operations.

Portable Electric Drill 3. Curriculum for House Wiring Study demonstration and identification of common electrical materials such as wires cables switches fuses ceiling roses PVC Conduits PVC Channels and allied items tools along with electrical instruments such as voltmeter ammeter and multimete Study of electrical safety measures and demonstration about use of protective devices such as fuses MCBs. It is a finishing tool used to make the wood surface smooth.