Types Of Holding Tools In Workshop

A6 Vise Grip is a tool used to grip the stock tightly enough to hold the object.

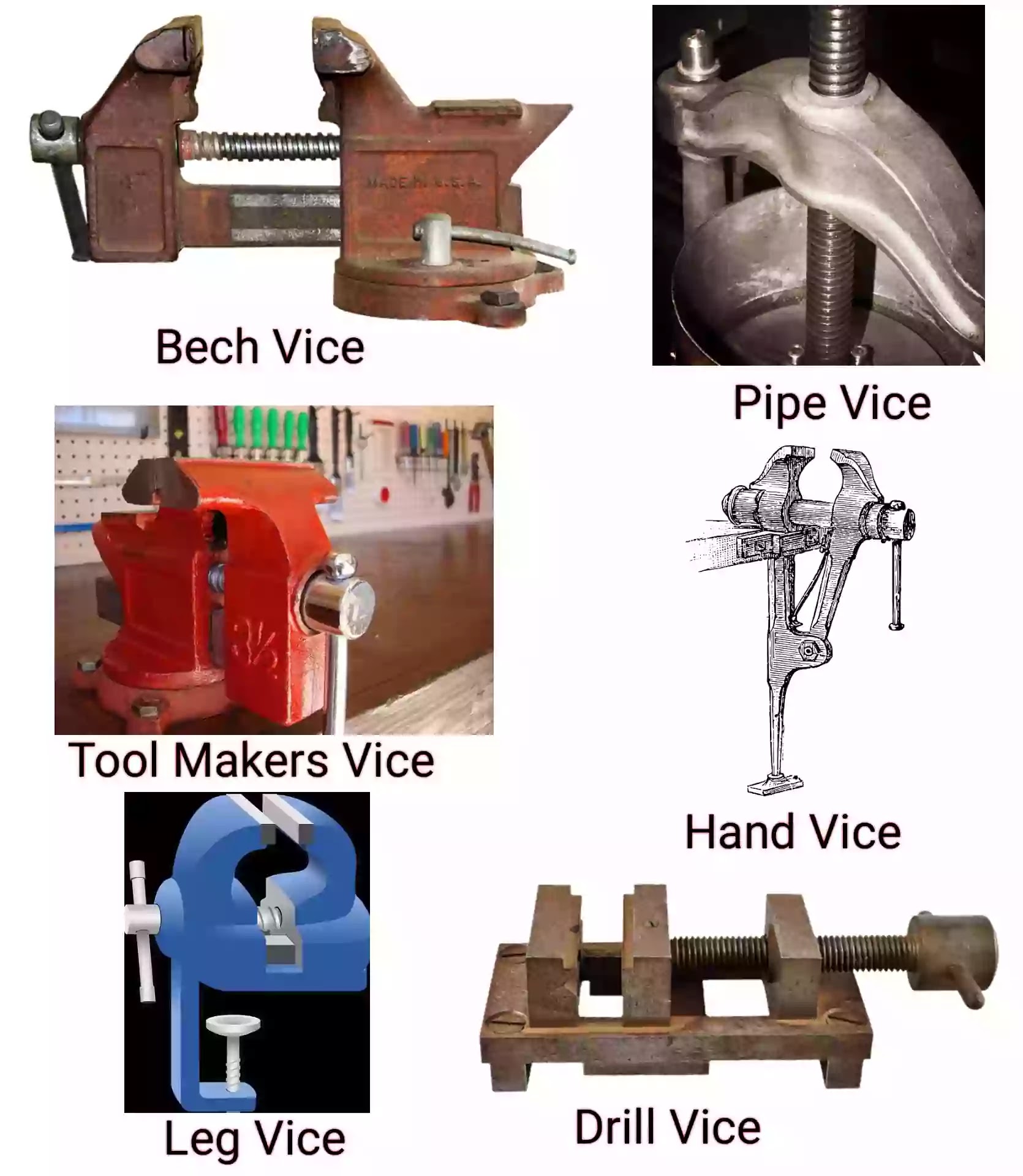

Types of holding tools in workshop. Take a look at the hydraulic wedge spreaders we have on offer by clicking the button above. Bench Vice A bench vice figure 20 is the device for holding the workpiece where most hand processes to be carried out. At this length a workshop can begin to address ideas and concepts in some depth and teach some skills.

The body of the vice is made of cast iron while the two clamping jaws are made of hardened tool steel. This type of workshop is more than long enough for participants to get bored or overwhelmed. This hydraulic wedge is a perfect workshop tool for separating stubborn joints even those with fitted ring grooves.

Toolmakers vice The Detailed Explanation of Work Holding Devices was HERE 2MARKING TOOLS. Holding Tools used in Engineering Workshop. The bench vice is a device commonly used for holding the work pieces.

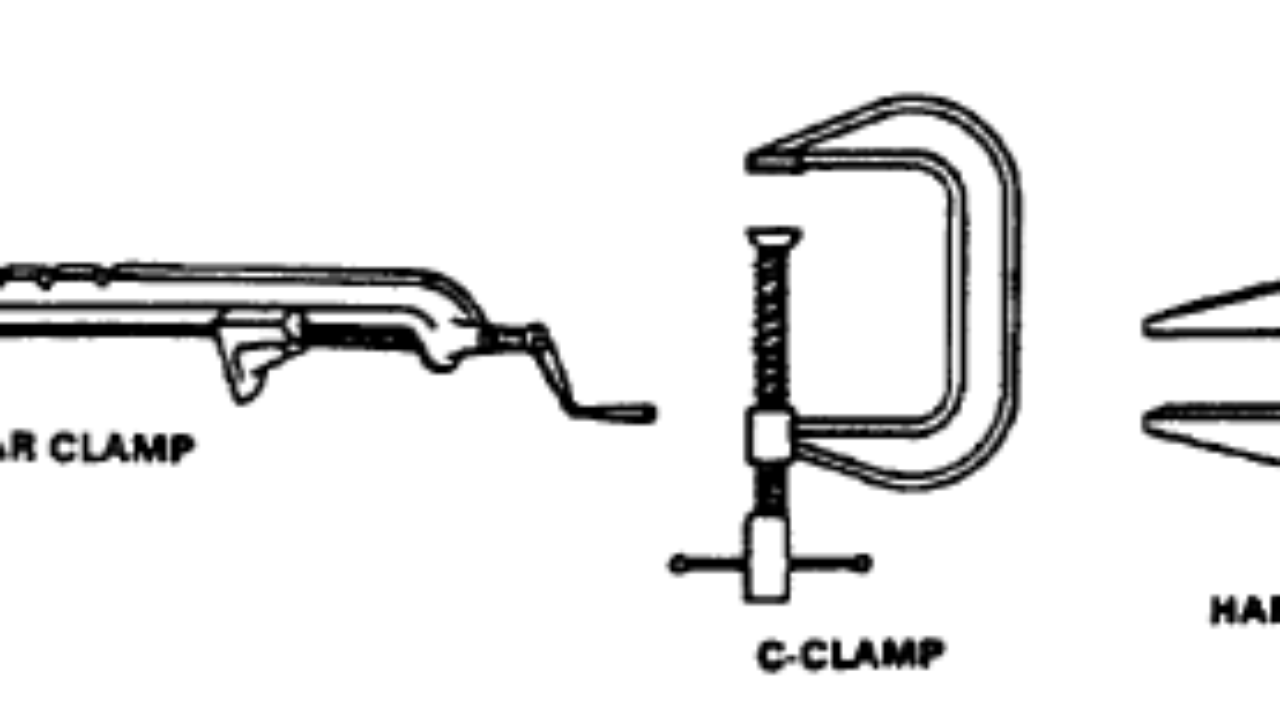

A5 Handvise V block with clamp is used to hold metal stocks for small machining operations. They are used to hold all types of components between jaws Fixed Jaw and Movable Jaw. There are other similar types of such clamps named as rack clamp screw clamps light duty parallel clamp adjustable bar clamp G or C-clamp and double bar clamp which are useful for holding different sizes and shapes of wooden jobs.

Marking Tools can vary wrt. One of the most commonly used work-holding devices is also called a drill press vise. Marking tools in workshop are Surface GaugeSurface PlateMarking TableScriberPrick PunchCenter PunchDividerTrammelBevel Square.

The greater the pressure applied to the handle the tighter is the work held. When the vice handle is turned in a clockwise direction the moving jaw forces the work against the fixed jaw. They are made of Steel or High Carbon Steel.