What Are The Different Types Of Cutting Tools Used In Center Lathe

Single -Point Cutting Tool.

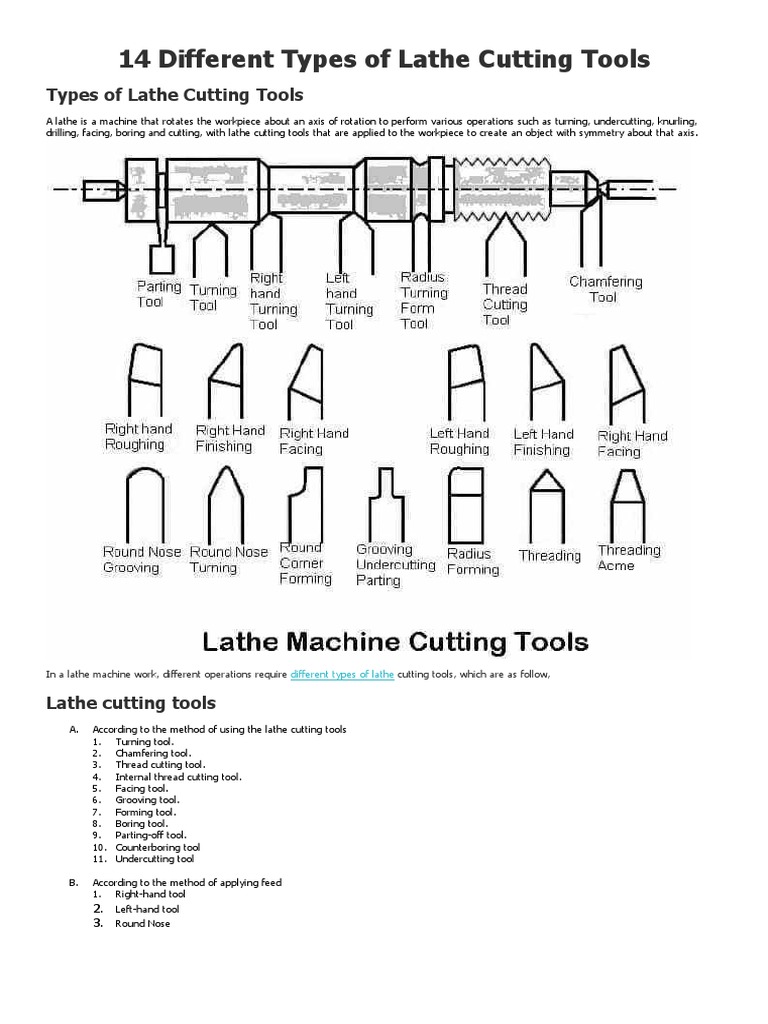

What are the different types of cutting tools used in center lathe. The most basic cutting operation on a lathe is straight turning. Tapping is the operation of cutting internal threads of small diameter using a multipoint cutting tool called the tap. R otational cutting tools that you can use for the removal of materials.

By far the most common type of operation performed on a lathe is the removal of metal by cutting. Milling Milling is typically used to produce parts that are not axially symmetric and have features such as holes slots pockets and contours. It can shape different materials to the desired shape by using several lathe cutting tools via several operations eg turning undercutting knurling drilling facing boring and cutting.

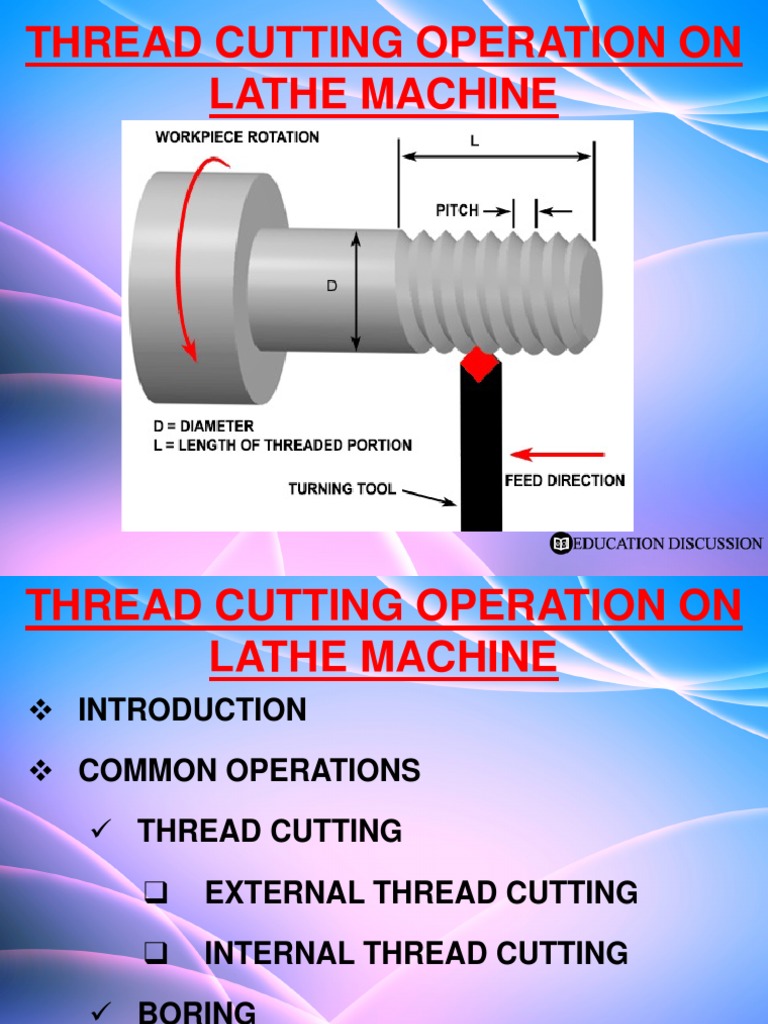

It is also used for attachments of tools like drills tap etc. Students are introduced to ANSI turning insert nomenclature tool holders and boring bars. Thread cutting tools are used to cut a thread on the lathe part.

This is a type of lathe that is currently widely used and can perform operations such as turning end face grooving knurling and threading. There are two types of cutting tools in this category Single-Point Cutting Tool. For to make the cut deeper the parting tool is pulled out and transferred to the side for the cut and to prevent the tool from breaking.

It is used to support the job when a chuck is used at the headstock too. In lathe processing cutting is performed by pushing a rotating cylindrical workpiece against a cutting tool called a tool bit which is attached to a spindle. They also learn about tools used for centerline machining such as twist drills taps and reamers.

Multiple point tools such as drills end mills taps and reamers will be discussed separately. Learn how to identify the components of common turning tools and how those tools are used in everyday turning processes. Cutting tools on a lathe usually have a single cutting point.