What Are The Five Safety Precautions Use In Machine Workshop

Wear shirts or uppers with sleaves cut off or rolled.

What are the five safety precautions use in machine workshop. Unsuitable clothing Large loose clothing unbuttoned shirt wearing neckties. Wear safety shoes if heavy work is being done. Never put other things on the milling table while working on the job piece.

Always stop the machine for making measurements and adjustments. Never wear a watch loose clothes while operating a milling machine. The following safety precautions or guidelines are generally adopted for every metal cutting or machining shop.

This will embed particulates into the precision machine parts and will drastically reduce the life of the machine. Safety Precautions Always Wear Approved Safety Glasses Rollup Sleeves Remove Tie And Tuck In Looseclothing Never O Lathe Machine How To Remove Lathe. Paying no regard for others working near you.

Wear clothing suited for the job wear shoes with thick soles. They must be strictly followed for safety. Always clamp the work and tool properly with correct size of work and tool holding device.

Specific safety guidelines for some of the machine process like lathe drilling shaping planning slotting grinding milling and finishing operations are also described in the following. Untidiness Overcrowded passageways objects on the floor grease or oil on the floor. Dont wear rings watches braslets or other jewellery that could get could get caught in moving machinery.

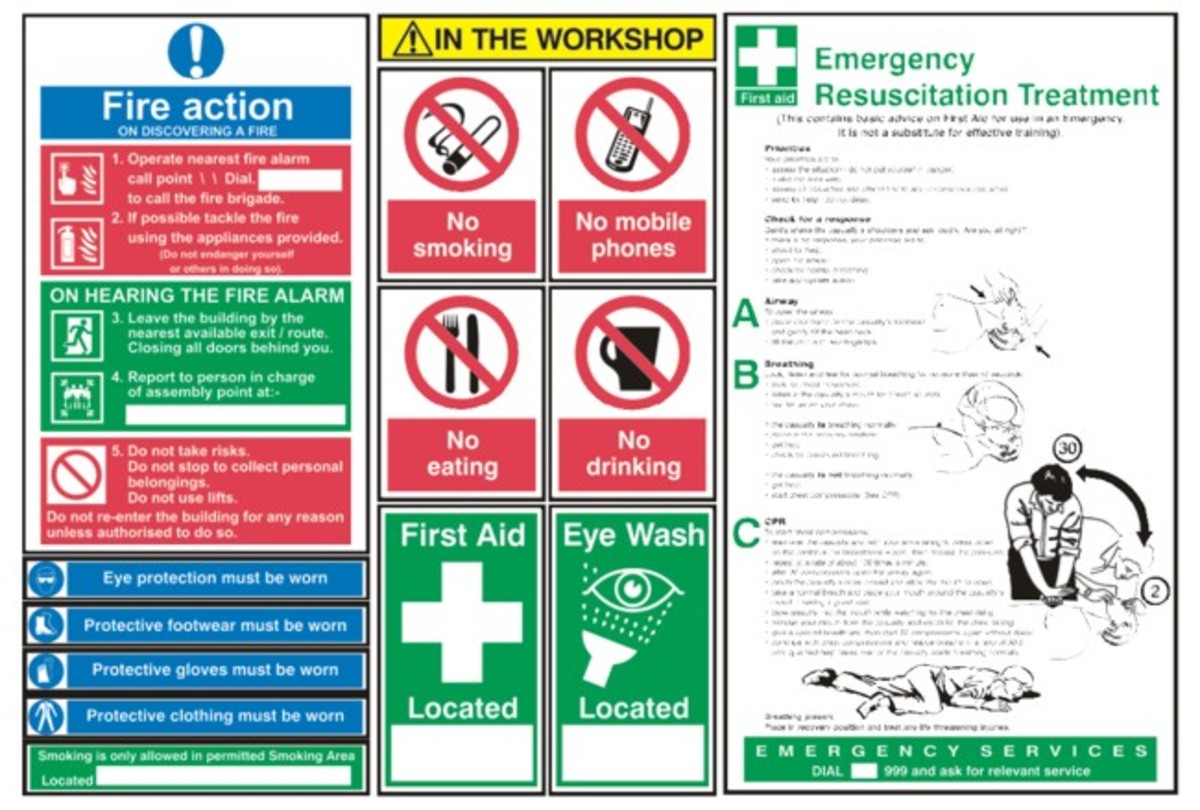

Dont wear neck ties or loose turn clothing of any kind. Safety precautions for Milling Machines. Safety Precautions can be defined as measures taken in the workshop to avoid accident or harm which one may encounter in the workshop.