How To Sharpen Carbide Tipped Lathe Tools

For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools.

How to sharpen carbide tipped lathe tools. Carbide does not lend itself well to offhand grinding although it can be ground that way. Assuming youre talking about brazed carbide tools the best way is with a high speed wet diamond wheel mounted on a machine with a table that tilts to establish front and side relief. I started at a time when there were no carbide tipped tools.

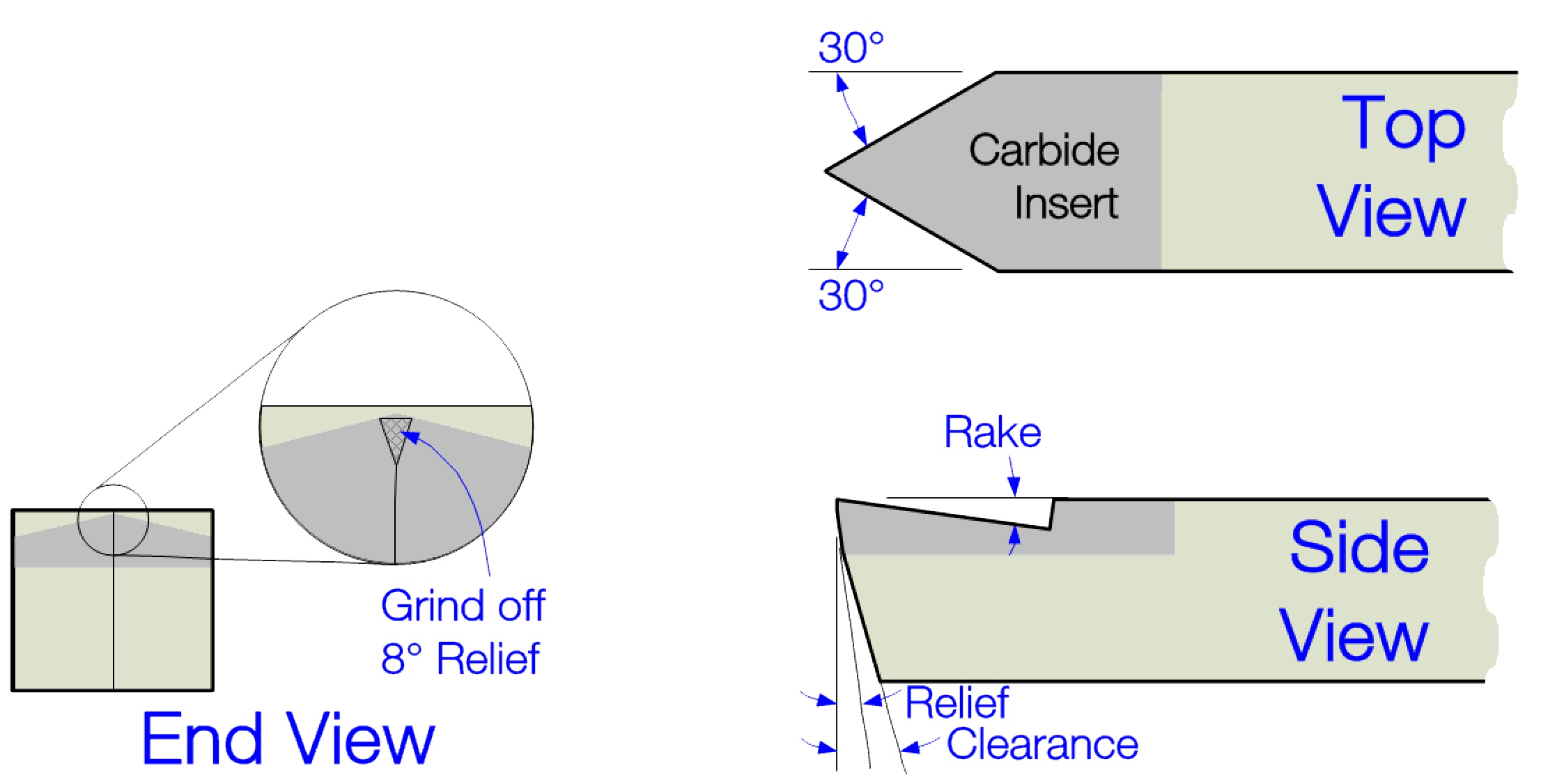

Carbide tools cant be sharpened with any old knife sharpener though. The relief angle under the cutting edge is 6 aka the end relief angle and the front edge angles away the tip at 15 aka the end cutting edge angle. Dont Forget the Other Face of the Tool.

They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with 7. It is a sled which rides atop the SVD-110 Tool. As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner.

These can be augmented with a variety of jigs to sharpen specialty shapes of lathe tools. When grinding the turning tool should be placed in the horizontal center of the grinding wheel and the tip of the tool should be slightly upward for about 3 8 When the turning tool contacts the grinding wheel it should move horizontally in the left and right directions. It takes a special grinding wheel made of silicon carbide abrasive When I was an apprentice that is all the shop had and we used a lot of brazed on tools in the shop.

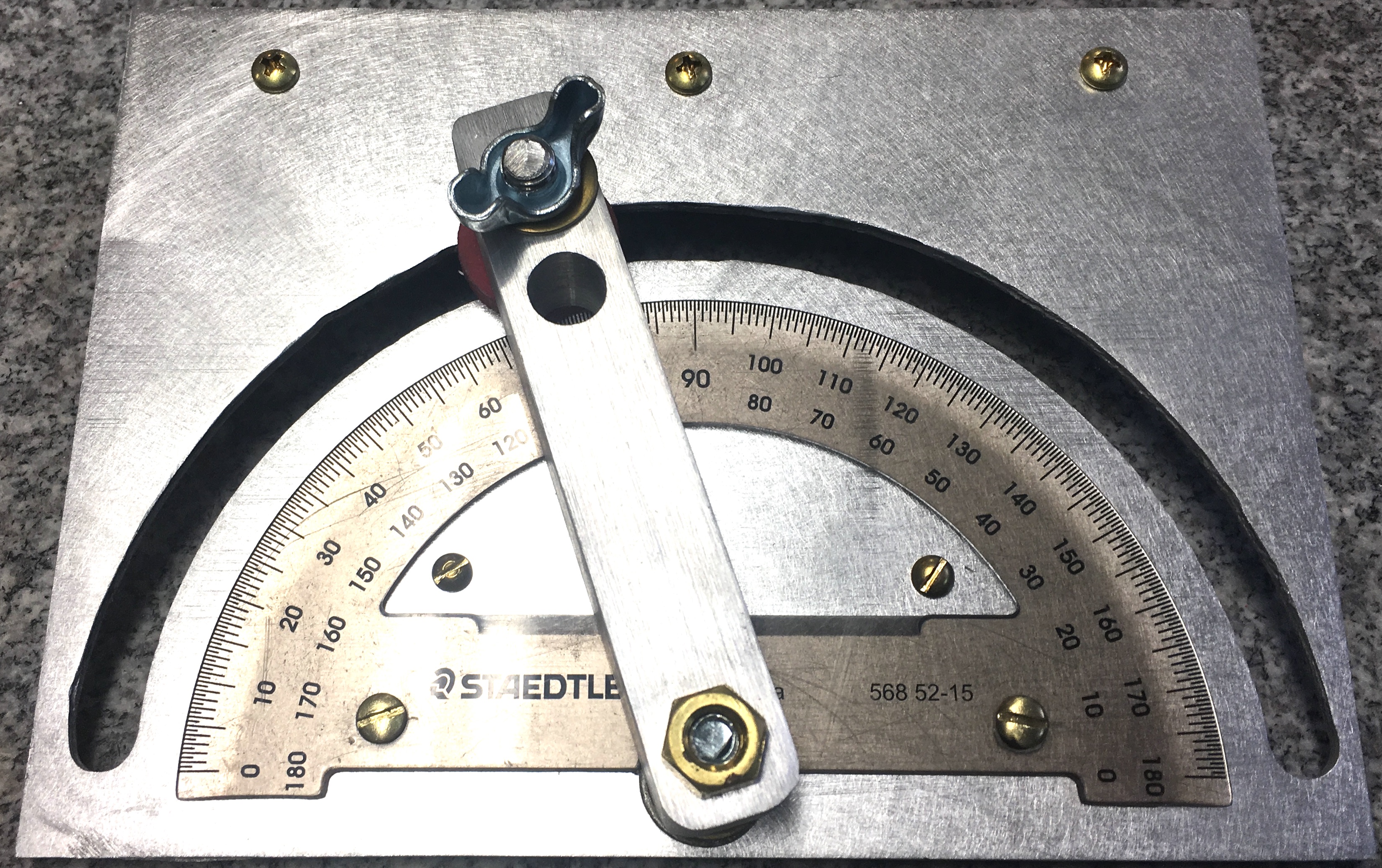

Adjust the rest as needed so that you achieve the necessary grinding angle for your particular tool. Carbide tools can be sharpened on an ordinary bench grinder but it does not do the best job in terms of finish. In this video I explore different aspects a slow speed grinding.

Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. In particular the angles must be precise for best cutting action. How to use a slow speed grinder to sharpen carbide tooling.