Types Of Measuring Tools In Workshop

Measuring Tools in Workshop 3a.

Types of measuring tools in workshop. Tap is a hardened and steel tool used for cutting internal thread in a drill hole. Therefore for removing those errors from a workpiece some measurement tools are devised by engineers such as surface texture measurement device tolerance measurement device screws threads measurement device and so on. Hand tools can accomplish a large portion of carpentry work given enough knowledge proficiency and time but power tools are a step-up in every aspect.

Calipers are classified into two types. Each set consists of a tapper tap intermediate tap and plug or bottoming tap. Many of these instruments are still in occasional use in my workshop where I build model steam engines whilst others are purely part of.

Power tools are necessary to set up a workshop or field practice and take carpentry to a professional level such as. The protractor dial is graduated in degrees with every tenth degree numbered. Workshop Measuring Tools A private collection of drawing instruments slide rules and mechanical calculators as well as a few microscopes and miscellaneous items.

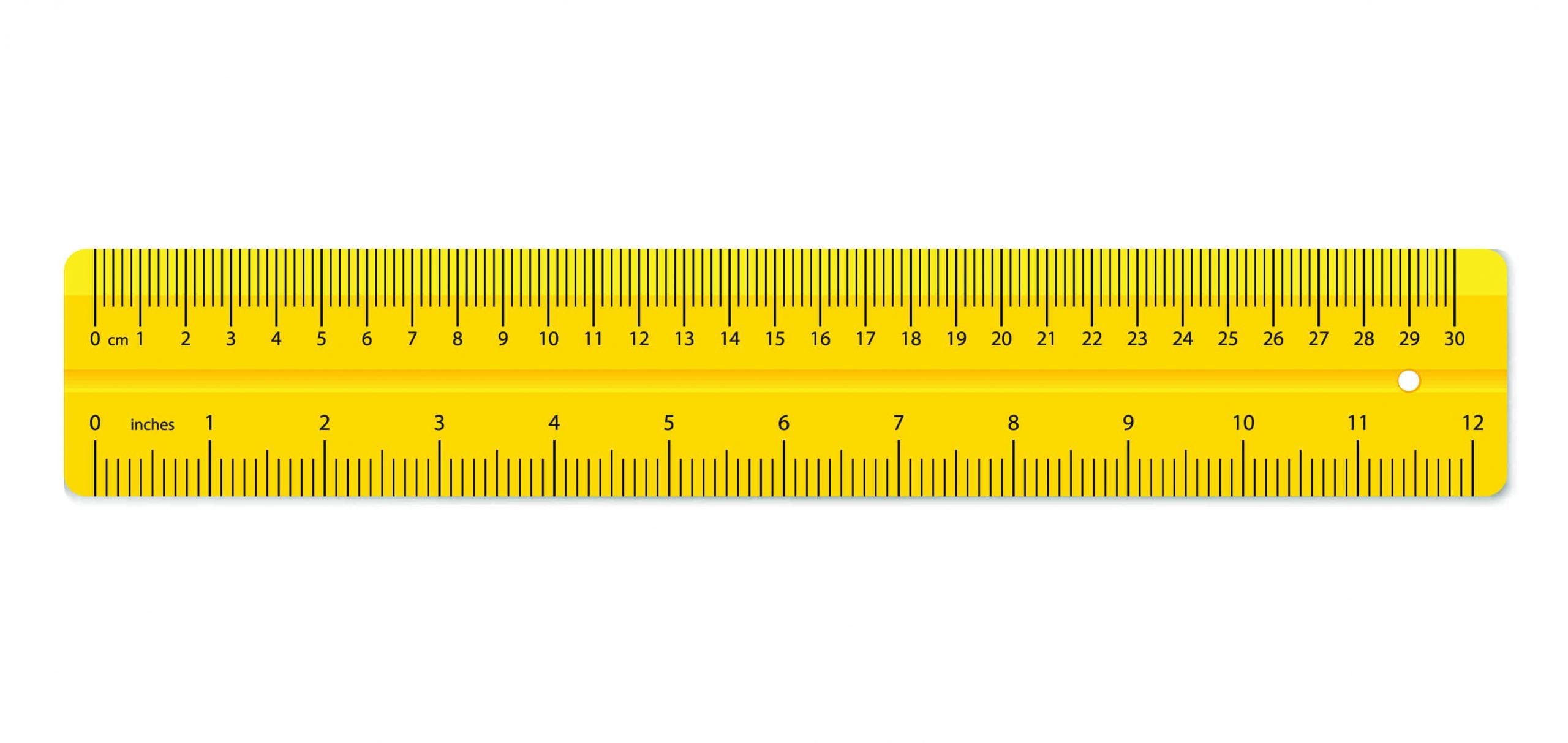

The detailed explanation of 10 Measuring Tools was HERE. Determine the scale of your plans. Climate and environment tools.

They are 3 types of Marking tools used in the fitting workshop and are as follows. The markings will never fade ensuring youll be able to mark out correct. Steel rule.

For instance if the plans read ¼ inch equals one foot you will use the ¼ inch scale on the ruler. Taps are made of high carbon steel. Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting Workshop.